Features & Benefits

EES Amended Silicates (AS) captures 90+% of vapor phase mercury from coal-burning power plants, enabling plant operators to satisfy mercury compliance standards, including the strict MATS (Mercury and Air Toxics Standards). Additionally, EES Amended Silicates™ offers operators significant direct and indirect economic advantages over traditional carbon-based mercury removal products.

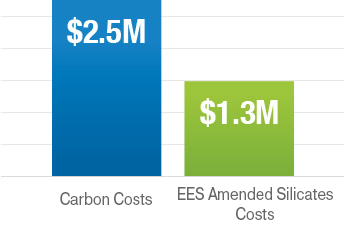

More Cost Effective than PAC

An EES Amended Silicates-prepared economic study for a 400 MW plant shows the annual cost of mercury removal using EES AS is $1,265,820 less than the cost of using PAC (Powdered Activated Carbon). The study incorporates results from actual field trials of AS, comparing projections for usage of the EES Amended Silicates product with brominated activated carbon. What’s more, since AS does not contaminate the plant’s fly ash, enabling its sale for use in concrete (see the EPA’s study on fly ash here), a plant using AS can realize an additional $2,450,350 in revenue and transportation and landfill cost savings. The study predicts that a 400MW plant using AS will readily meet applicable mercury removal standards, while realizing an upside of over $3.7 million annually when compared to carbon-based removal agents.

An EES Amended Silicates-prepared economic study for a 400 MW plant shows the annual cost of mercury removal using EES AS is $1,265,820 less than the cost of using PAC (Powdered Activated Carbon). The study incorporates results from actual field trials of AS, comparing projections for usage of the EES Amended Silicates product with brominated activated carbon. What’s more, since AS does not contaminate the plant’s fly ash, enabling its sale for use in concrete (see the EPA’s study on fly ash here), a plant using AS can realize an additional $2,450,350 in revenue and transportation and landfill cost savings. The study predicts that a 400MW plant using AS will readily meet applicable mercury removal standards, while realizing an upside of over $3.7 million annually when compared to carbon-based removal agents.

Fly Ash Revenue & Other Benefits

Mineral-based AS does not contaminate fly ash, enabling plants to sell their fly ash for use in concrete. An economic study indicates a 400 MW plant could realize as much as $2.4 million through fly ash sales and the elimination of associated transportation and landfill costs. In addition, AS is non-flammable and non-corrosive, simplifying its storage and handling. AS also requires no additional chemicals for optimal performance and its inert mineral-based design successfully balances plant operation and potential environmental issues.

Smaller Carbon Footprint

Amended Silicates (AS) has a significantly smaller carbon footprint than PAC. The production of AS generates just 10% of the carbon dioxide released in the production of an equivalent amount of PAC. In addition, because the chemical compound created in the AS mercury removal process is non-flammable and non-corrosive, it does not negatively impact the plant itself. AS is built on a widely available, naturally occurring mineral base, ensuring an ongoing supply. AS can be readily integrated with most existing sorbent injection systems and does not require additional chemicals, halogens or other additives to be effective.

Successful completion of more than 70 full-scale plant tests demonstrates that AS products can be used effectively and economically in a wide variety of plant configurations and with the range of potential fuels – PRB, sub-bituminous, lignite. Regardless of fuel type and/or plant configuration, EES Amended Silicates mercury removal products offer enormous economic advantages for mercury control.