AS-HgOX

Mercury Oxidation Challenges

To improve the mercury capture co-benefit of air quality control devices and activated carbon, power plants often first treat the flue gas with halides in order to oxidize the Hg and improve overall mercury capture in wet scrubbers or with PAC products.

While the addition of these halides to the coal feed does indeed augment the mercury oxidation, there are inherent issues and limitations to these systems:

- Halide additions at typical furnace temperatures (> 2000º F) generate acid gases that corrode the balance of the plant.

- Plants using halides often have to replace their Air Heater baskets in just 12–24 months (in typical use AH Baskets can last up to 5 years!).

- Replacing corroded AH baskets results in expensive, unscheduled and unplanned downtime for a plant.

- Halides also contaminate wastewater discharge; regulations for which are currently expanding.

Avoid Unscheduled Outages at Your Power Plant and Save Money in the Process

How It Works

Plant corrosion typical of halide use

EES Corp’s AS-HgOx product augments the oxidation of mercury and improves the co-benefit of the plant’s air quality control devices, but without the corrosive gases and damage to the balance of the plant.

- EES Corp’s AS-HgOx product promotes oxidation of Hg via chemistry on the particle surface.

- AS-HgOx is injected downstream of the boiler, at much cooler flue-gas temperatures (just 300–600 degrees F) than halides, via a typical dry sorbent injection system.

- AS-HgOx is ideal for those plants now utilizing halide coal treatments that are

- Equipped with Wet FGD SO2 Scrubbers

- Like many other successful EES Corp products, AS-HgOx is built on the company’s proprietary and proven amended-substrate platform.

Corrosion Free Hg Oxidation -The Clear AS-HgOx Advantage

AS-HgOx does not generate the damaging halogen gases, which also means:

- There is no change in the flue gas environment;

- There are no highly corrosive gases;

- There is no increased concentration of existing trace acid gases (HCl); and,

- Ultimately,no corrosive damage to the plant, putting an end to expensive, unscheduled outages.

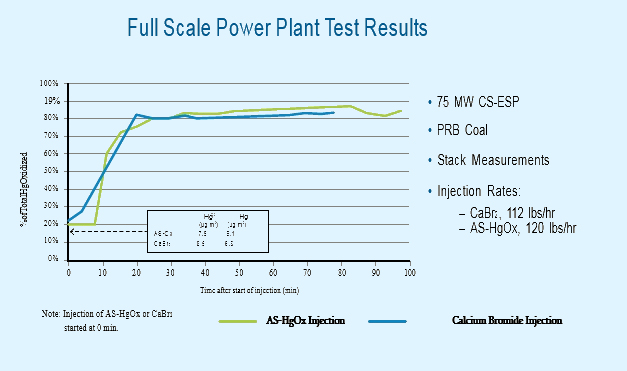

AS-HgOx is as effective as the typical halogens in oxidation performance while costing the same as Calcium Bromide, and even less than Calcium Chloride or iodine additives.